KINGSWAY, FIRE DAMAGE

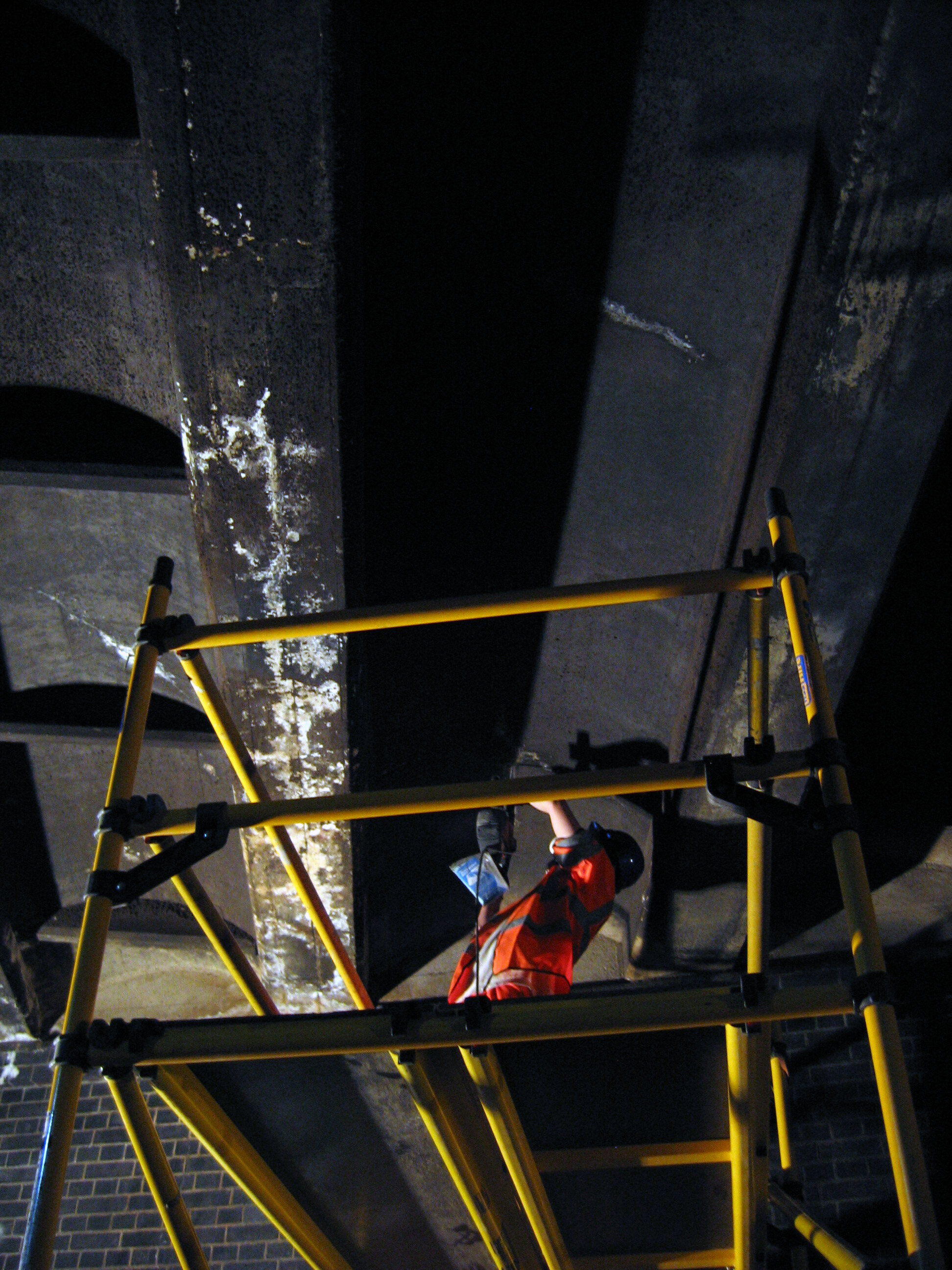

Tempo-PCE were awarded the contract to repair the structural damage caused by the Holborn Fire in 2015, having worked on the maintenance of Camden’s service tunnels for several years. In close collaboration with the Structure’s Team, we developed the strategy as Principal Contractor, liaised with utility companies, and assisted in the challenge to keep the public informed without disclosing safety critical details.

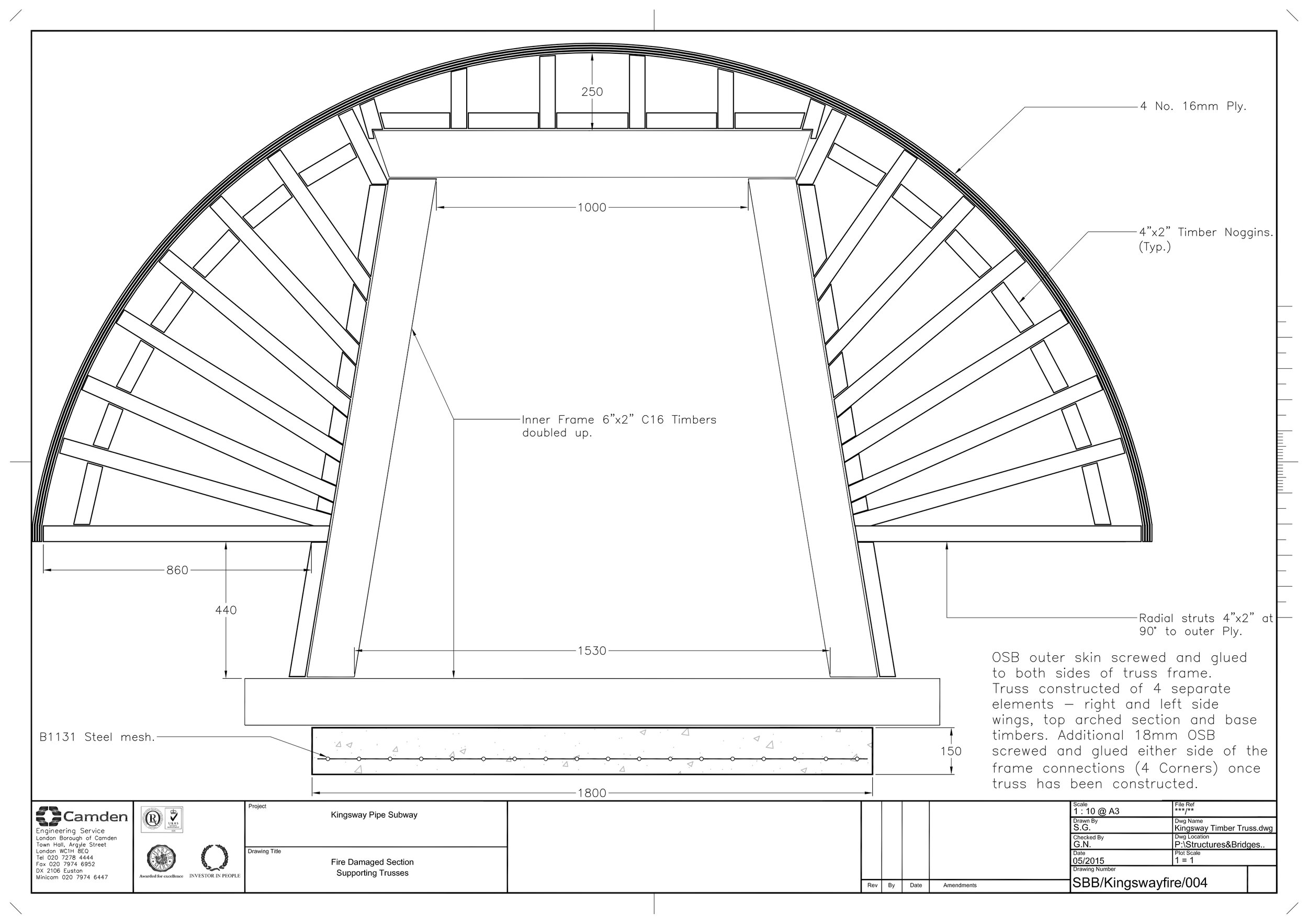

Tempo-PCE designed and implemented a radial truss system to support the damaged arch to allow the road to reopen to a 40t loading. The temporary works system allowed a safe method of work to carry out brick replacement of over twenty thousand bricks under a live road. Once these repairs were successfully completed, cementitious injection was applied to tie the new and existing brick rings together, and ensure bonding to the concrete saddle.

LADYWELL BRIDGE, LEWISHAM

The London Borough of Lewisham commissioned Tempo-PCE to waterproof the service trays on a road bridge with acrylic resin injection. Ladywell Bridge, a 150m multi span concrete structure, carries the B236 over the Ravensbourne River and the Mid-Kent rail line. Carrying out the injection from below allowed waterproofing works to be successfully completed while the road bridge remained fully operational, and all services left in place.

Consulting engineers INGealtóir oversaw the structural elements of the works. After an on-site feasibility study and the waterproofing of a trial vault, the full span was waterproofed, achieving approx. 97% reduction of water ingress. In addition, remedial works were completed to arrest concrete spalling and deterioration of girders/beams and soffit, as well as repairs to the exterior brick skin.

BAYNARDS BRIDGE, SURREY

Baynards Bridge carried the now defunct Cranleigh Railway Line over a local valley on the Cotswold Edge. Surrey County Council/ May Gurney commissioned Tempo-PCE to undertake the refurbishment of the brick arch barrel bridge, which involved the rebuilding of the outer edges of the brick arch, as well as structural and waterproofing injection. Works were carried out in three stages: firstly a series of substantial brick repairs, namely the careful removal and rebuilding of the four outer rings in damaged areas, brick stitching, tie bars fitting, and repointing. The second step was a waterproofing injection: to prevent the structural injection grout being diluted by water running through the structure, an umbrella of waterproofing resin was injected into the backfill. The last phase was the strengthening injection, where a custom mix of acrylic resin and micro fine cements was injected over a staggered 250mm grid. Drill holes terminated approx. half-way into the extrados brick ring. Injection was completed at low pressure, a maximum of 3 bar, and carried out to refusal. This allowed the grout to fill all reachable void, and penetrate around fragile existing services.

ALCONBURY WESTON BRIDGE, CAMBRIDGESHIRE

Alconbury Weston Flood Bridge is a 18C bridge, which carries North Road (C105) through the village of Alconbury Weston over a flood channel. The structure consists of five two-brick-ring arches and two 750mm concrete pipes either side of the brick arches. The arches vary in size, springing height and age. Following a Principal Inspection that had determined a reduced capacity of 7.5 tonnes, Atkins Ltd, on behalf of Cambridgeshire County Council, commissioned Tempo-PCE to increase the capacity of the structure to a 40 tonne GVW loading. The client was uneasy with the conventional methods of saddling/ backfilling by removal of and reinstatement of the road surface for this project, as this approach would have caused too great a burden on the local road network.

The alternative method of strengthening via a low-pressure injection into the backfill, was trialled in an onsite feasibility study by Tempo-PCE: Two alternative materials, a two-part polyurethane based grout and an acrylic and micro-fine cement mixture were used in the trial. The feasibility study allowed to design a tailor-made methodology and to confirm void ratios, as well as carrying out a post injection assessment. The Graham Cole Consultancy Ltd completed the trial assessment and post completion numerical analysis. A two-part, non-expansive PU grout was injected over a 500mm staggered injection grid. Post-completion cores revealed excellent saturation, re-bonded brick-arches, a consolidated backfill, well-bonded to the extrados, and the bridge achieved the desired 40 tonne loading.

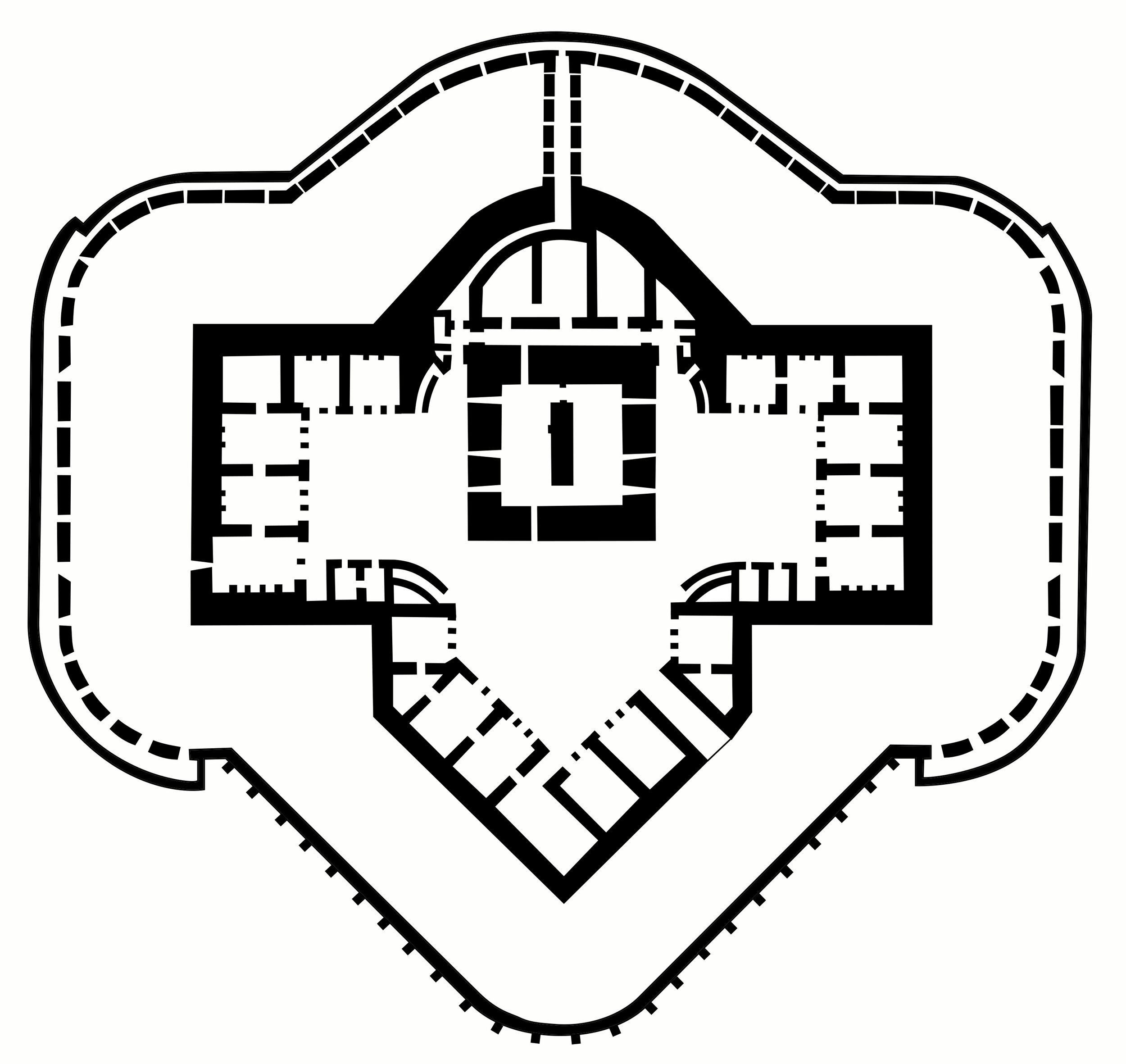

SOUTHSEA CASTLE

Constructed by Henry VIII in 1544 and an active military base for over 400 years, Southsea Castle was withdrawn from active service and purchased by Portsmouth City Council in 1960. Now a Scheduled Ancient Monument and popular visitor attraction, the castle’s brick parapets, which were built as an extension of the fortification in the 1850s and 1860s, required refurbishing to improve longevity by removing voids within the masonry created by washout and reduce to water ingress. Tempo-PCE were awarded the injection works on the strengths of our experience with heritage structures and lime injection.

Tempo-PCE injected the inner face and the top of the sea-facing ramparts: 30mm cores were drilled through the face brick to initially allow trapped water to drain from the masonry, they were then used for grouting . Then a 300 x 300mm staggered injection grid was drilled on top of the parapet and a specialist lime grout injected to refusal, using an air-driven diaphragm pump. All drill results and injected quantities were recorded and mapped. Over 3,000 holes were injected, considerably reducing future water ingress to the parapets.

NORTHERN LINE EXTENSION

The Northern Line Extension is currently under construction from Kennington to Battersea, terminating at the redeveloped Battersea Power Station. The extension will form a continuation of the Charing Cross branch of the line. Tempo-PCE won the segment repair contract to support FLO, the Ferrovial Agroman/ Laing O’Rourke JV, with the repairs to the concrete ring segments constructed by the tunnel boring machines. Repairs include making good and waterproofing to cracks, gaskets, holes and any other damage through the entire length of the bored tunnels from Battersea to Kennington, both north and south bound. Repairs were completed with PU and acrylic resins.

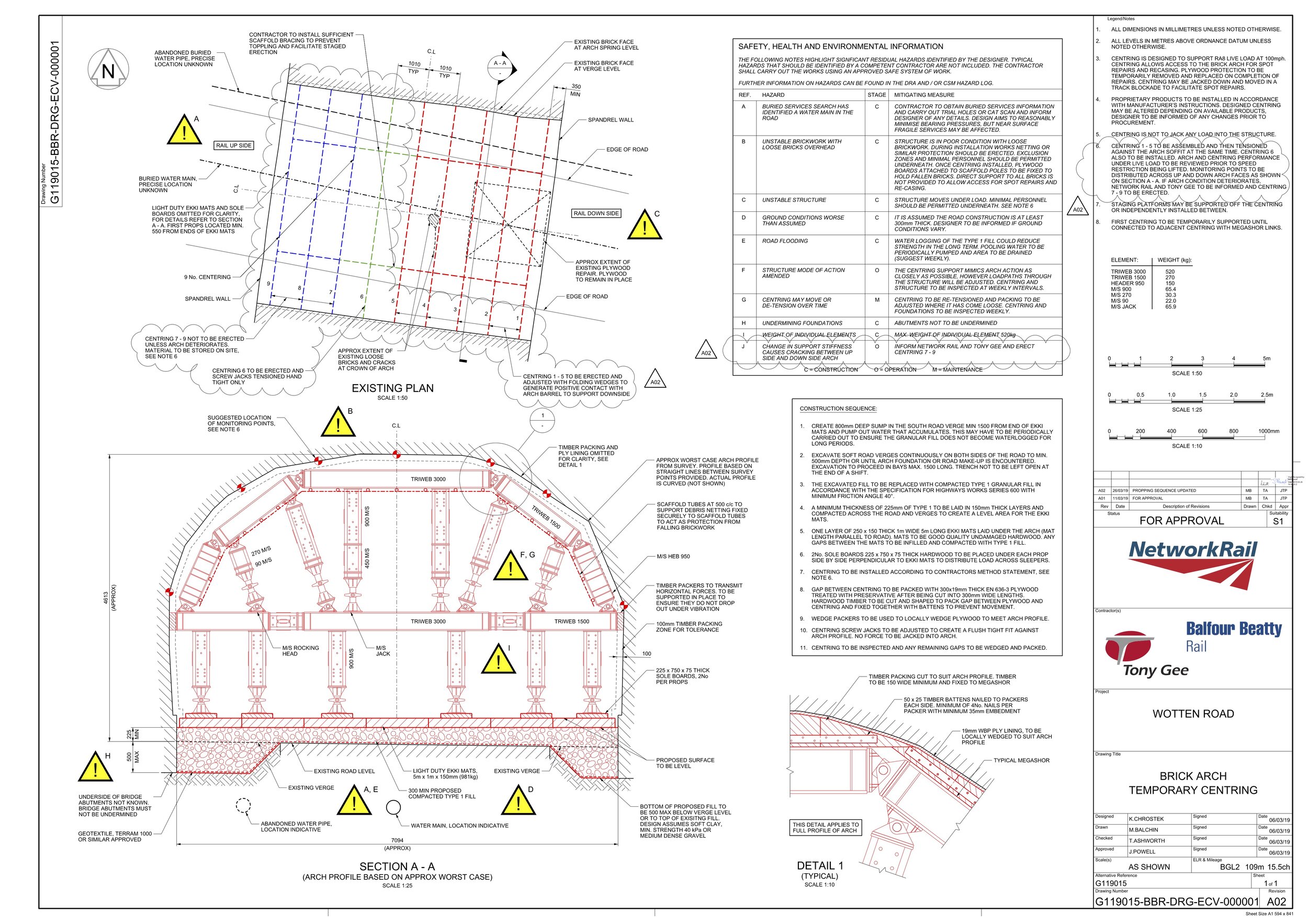

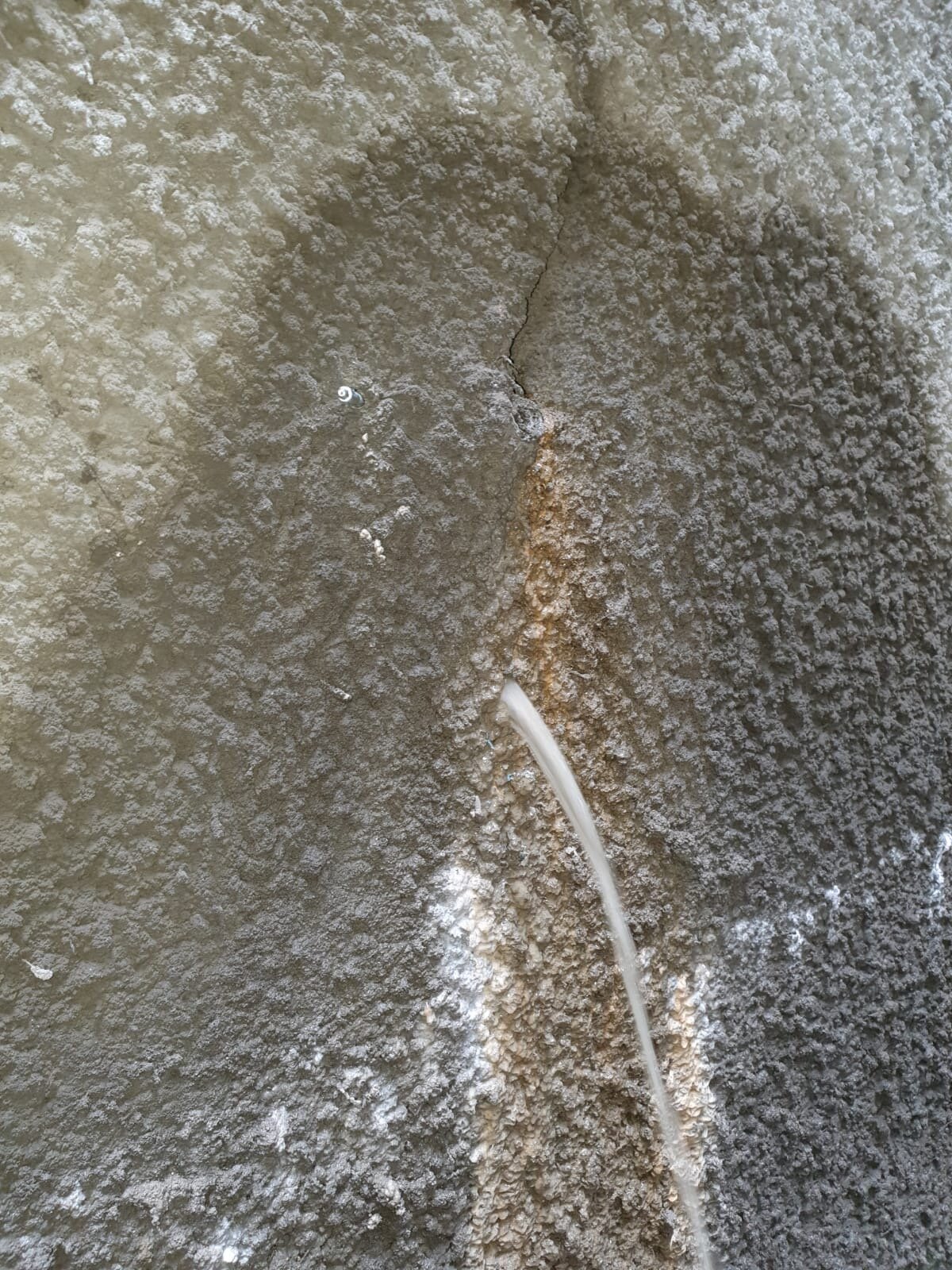

WOTTON BRIDGE

Wotton Bridge is a Network Rail structure carrying the Bristol-Birmingham line over a single lane country road in Gloucestershire. The five-ring red brick segmental arch with solid brick abutments showed a plug of brickwork active under rail load during a recent refurbishment. The arch barrel had been grouted and pinned, giving no visible improvement in stiffness in one section. Balfour Beatty and Tony Gee brought Tempo-PCE on board to carry out strengthening injection due to our experience with Normet UK’s ultrafine grout, a specialist cementitious grout with latex. The crown was drilled and injected, with clay used to close any material running out through missing mortar. The strengthening, in combination with brick re-casing, significantly stiffened the structure and deflection settled to about 0.90mm, leaving Network Rail “very impressed”.

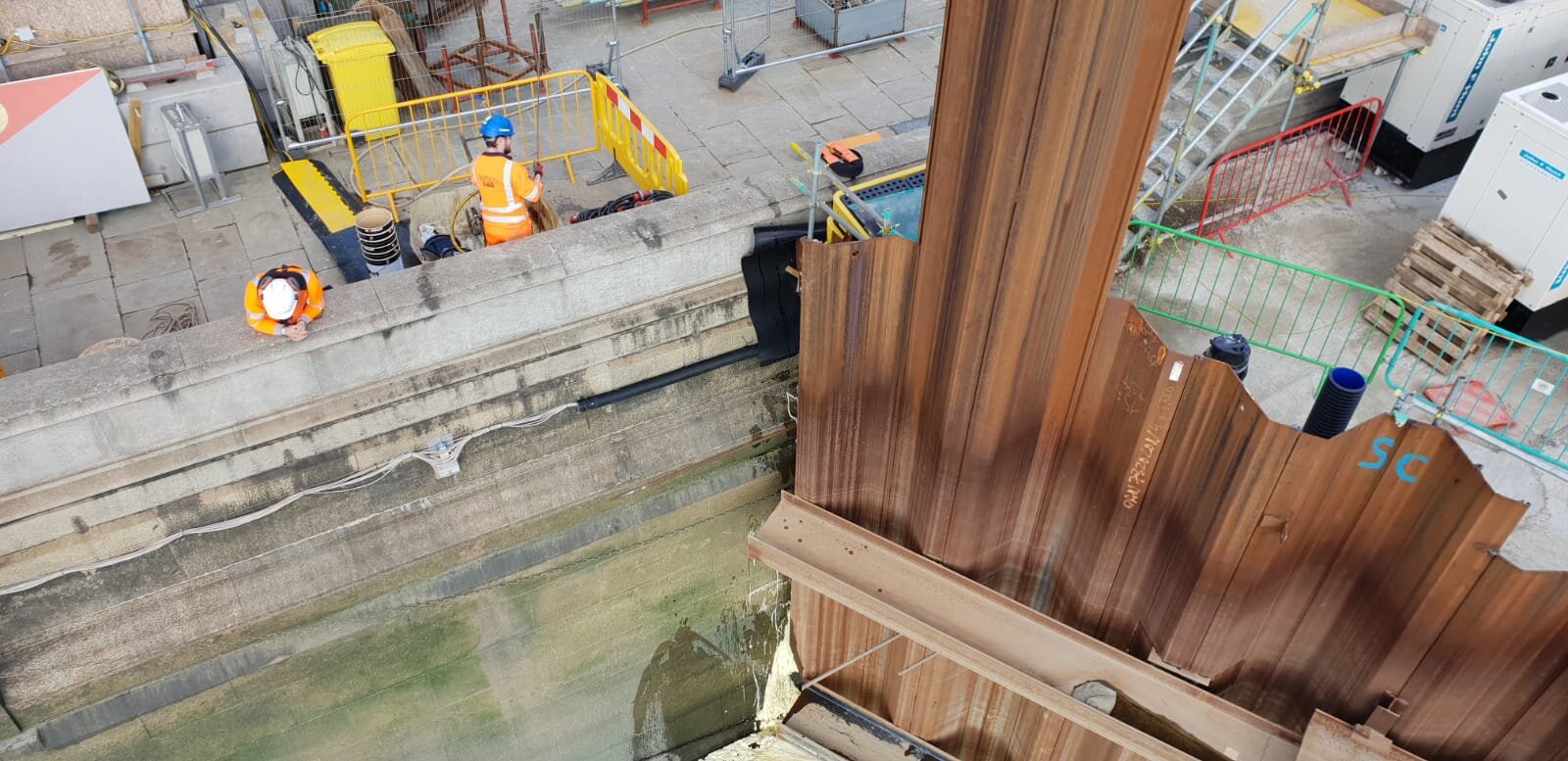

THAMES TIDEWAY

Thames Tideway will be a 25 km tunnel running under the tidal section of the Thames to convey almost all the raw sewage and rainwater that currently overflows into the river. Under construction at the time of writing, Tempo-PCE have assisted Tideway with a variety of services on several of the Central sites: We have worked on Albert Embankment Foreshore, Blackfriars, Chelsea Embankment, and Victoria Embankment to carry out leak sealing injection to the river wall and cofferdams, as well as waterproofing injection to SCL culvert tunnels, shafts, and inspection chambers.